Easy Servo Set Manufacturer

Introduction

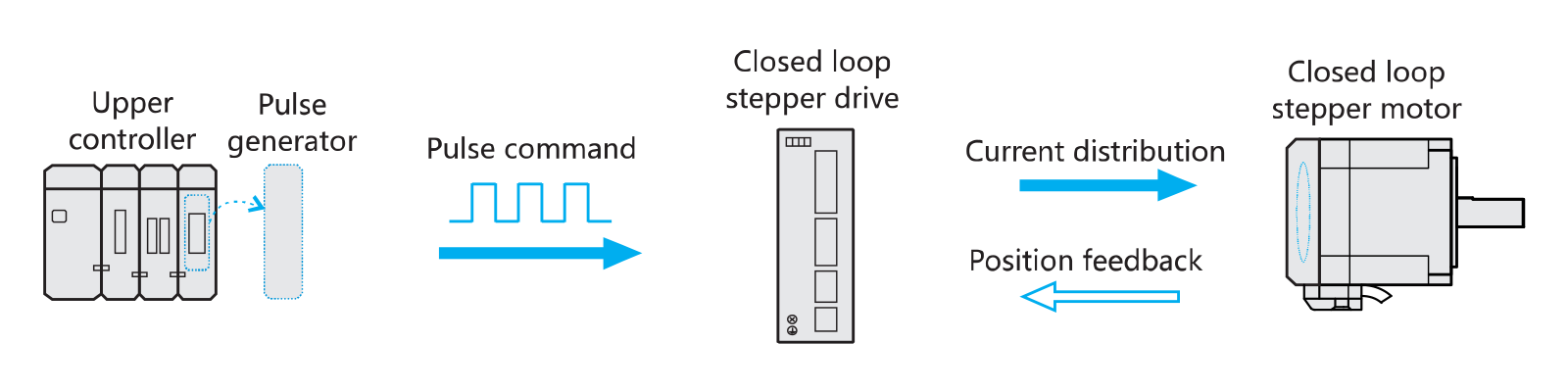

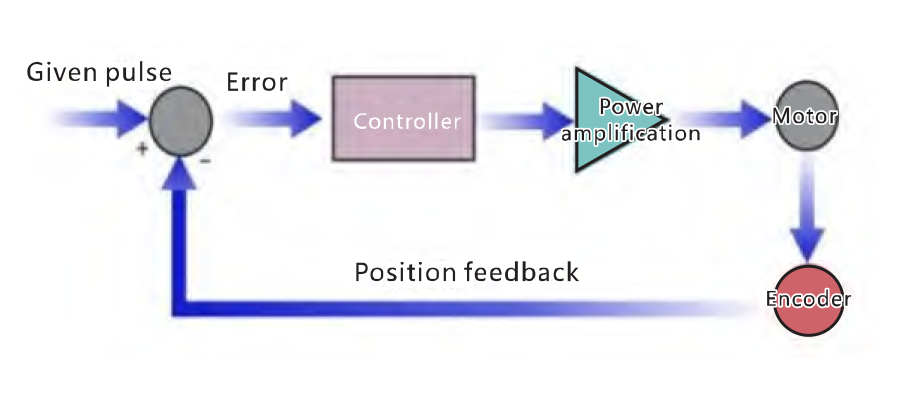

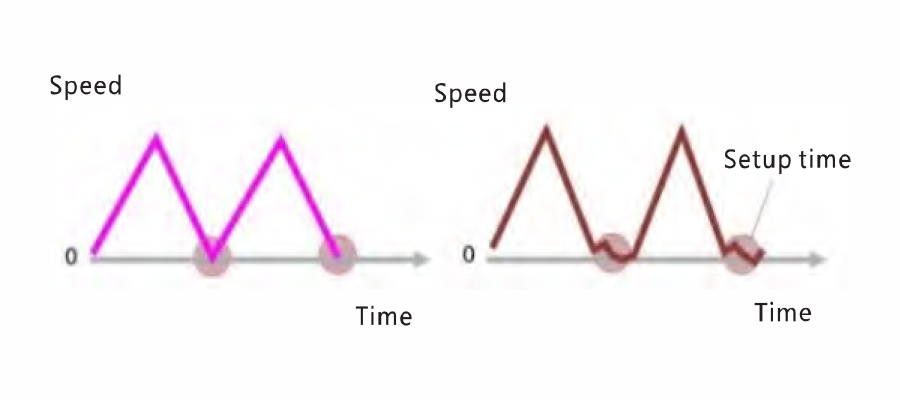

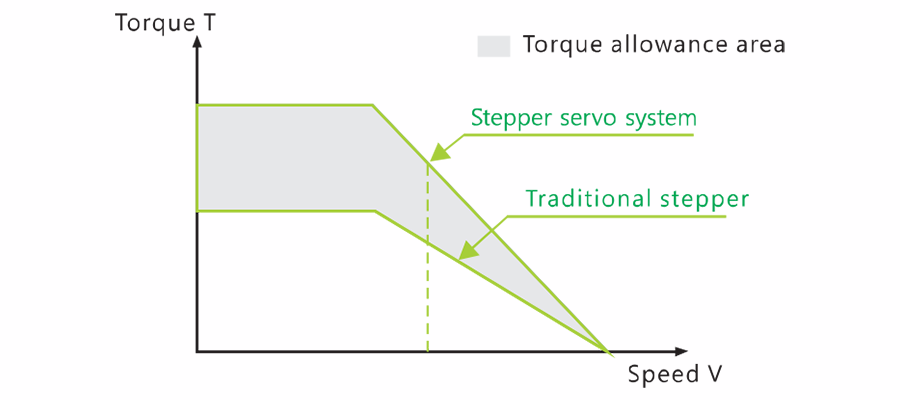

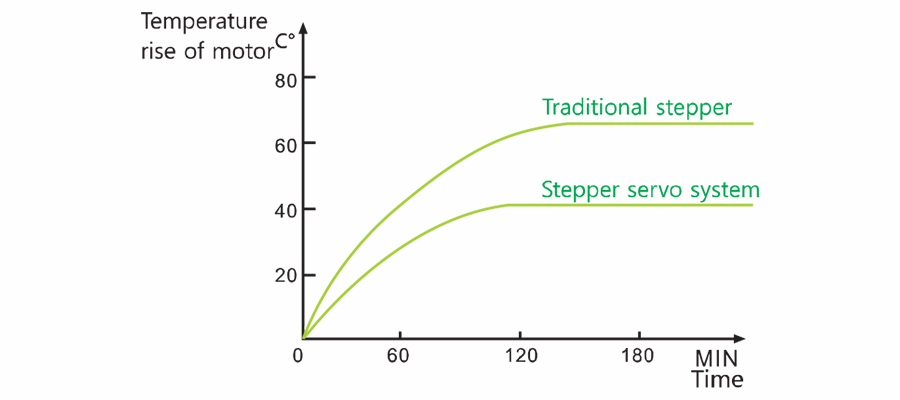

A Easy Servo set is a control motor system that produces high speed, high torque, high precision, low vibration, low heating, and no step loss by combining an open loop stepper motor with position feedback and a servo algorithm.

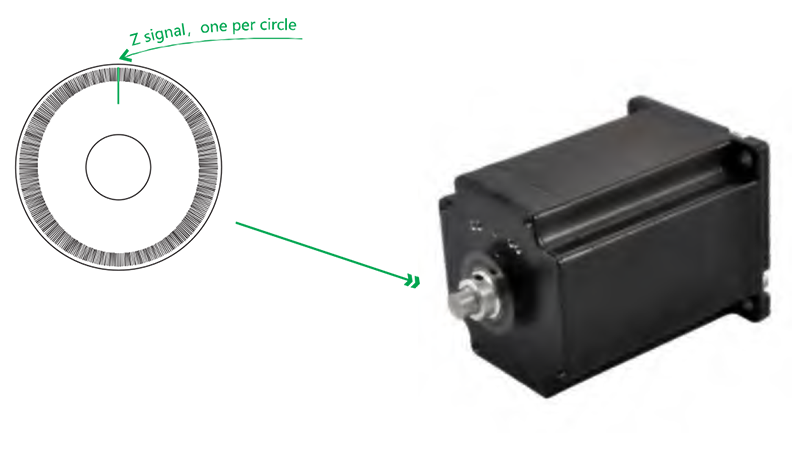

In an Easy servo set, an optical encoder for position feedback is mounted on the rear shaft of the open-loop motor.

The Easy servo set processes encoder position feedback to improve current and position control.

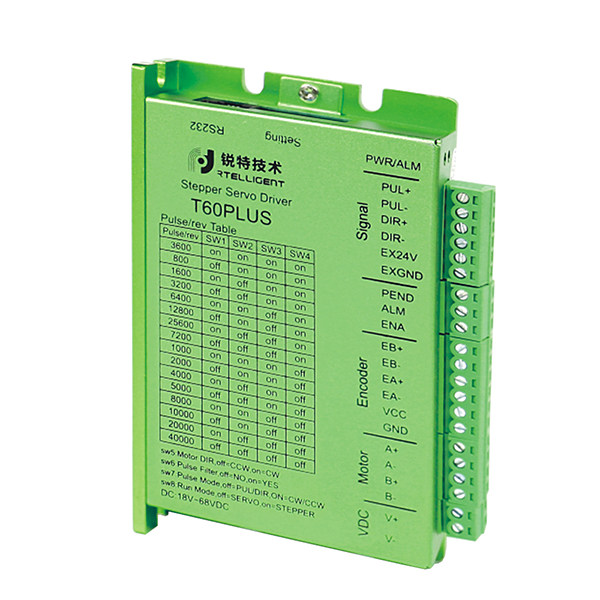

Rtelligent’s Easy servo sets provide a simplified solution for precise motion control. These systems combine servo motors and controllers with user-friendly software, offering a plug-and-play experience.

With built-in encoders and closed-loop control, easy servo sets ensure accurate positioning and velocity, making them suitable for applications ranging from CNC machines to 3D printers.

Their straightforward setup and compatibility with various control systems make them an excellent choice for both beginners and experienced engineers seeking reliable and hassle-free motion control solutions. Easy servo sets simplify complex tasks, enabling efficient automation and robotics in diverse industries.